Infrared Wisconsin is a Division of The Gardner Company Inc.

Infraspection Institute Certified level l & ll

Infrared Thermographer

608-834-8348

Infrared Inspection Services in Madison, and greater Wisconsin

Thermal Imaging of:

Flat roof moisture infiltration surveys and mapping

Quality assurance thermal inspections on new buildings

Grout filled cells in CMU (concrete masonry block)

Commercial Walk-in freezers

Agricultural and Industrial storage tanks

Radiant Heat Leaks under flooring

Mechanical systems

Electrical systems

EIFS - Exterior Insulated Finish Systems

Quality assurance thermal inspections on new buildings

Grout filled cells in CMU (concrete masonry block)

Commercial Walk-in freezers

Agricultural and Industrial storage tanks

Radiant Heat Leaks under flooring

Mechanical systems

Electrical systems

EIFS - Exterior Insulated Finish Systems

~ Service. Commitment. Experience. Knowledge. ~

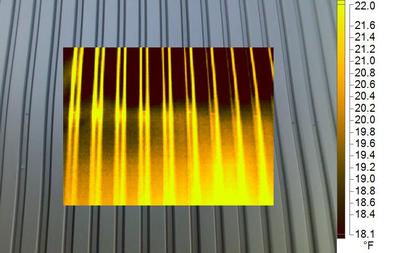

EIFS - Exterior Insulated Finish System

EIFS or synthetic stucco is used on many homes and buildings. This infrared image shows possible moisture infiltration originating from the roof to wall intersection. This problem usually stems from not installing a kickout flashing. This allows moisture to infiltrate the exterior cladding system causing damage to the structural members and may allow possible mold infestation.

Solving Problems with Infrared and GPR

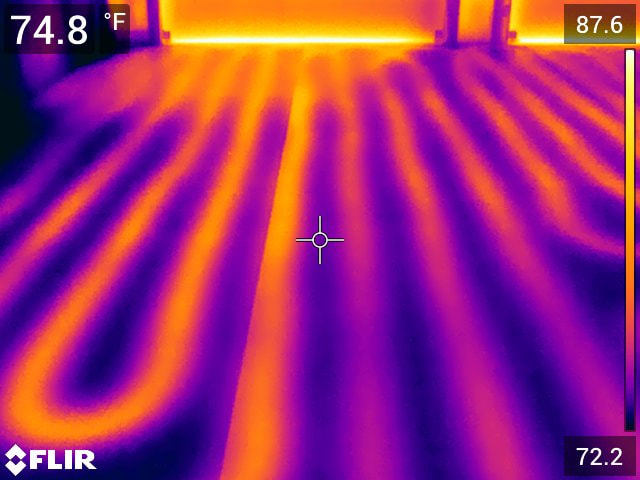

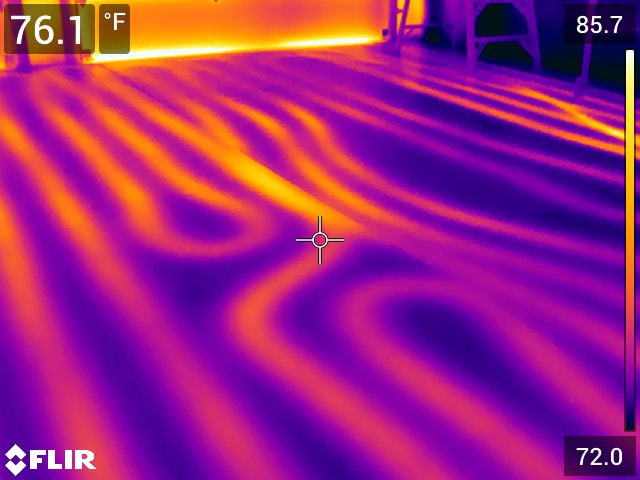

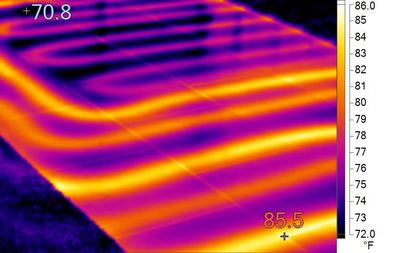

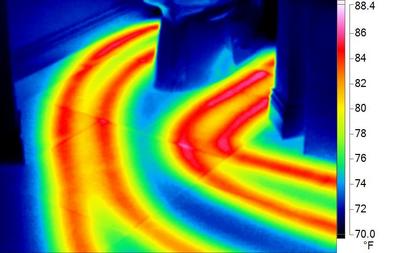

Recently a customer had a unique problem, he built a beautiful new garage to build custom cars in. The garage had in-floor heating and now he wanted a car lift installed. He needed 10 bolt holes drilled 1/2" x 4" deep into the concrete but he had in-floor heating lines running in all directions.

We were called in to do an infrared survey and locate the lines which is very easy with infrared however it cannot pin point the exact location and depth as needed for drilling. Lucky for the customer we also do (GPR) ground penetrating radar and concrete scans. We used the U.S. Radar concrete scanner to locate the exact locations of the lines and the holes were drilled.

Problem solved!

We were called in to do an infrared survey and locate the lines which is very easy with infrared however it cannot pin point the exact location and depth as needed for drilling. Lucky for the customer we also do (GPR) ground penetrating radar and concrete scans. We used the U.S. Radar concrete scanner to locate the exact locations of the lines and the holes were drilled.

Problem solved!

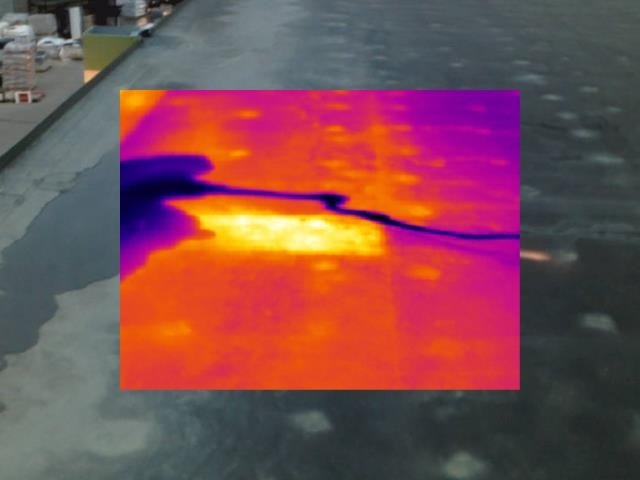

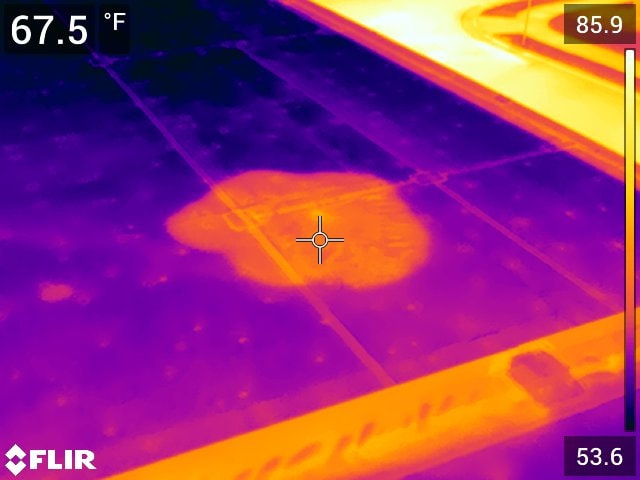

Roof Moisture Surveys

Images below show moisture infiltration under single ply roof membrane. This can only be seen with Infrared Thermography. However without an experienced and trained thermographer there are many false positives.

Water infiltration into the roof assembly must be addressed immediately, damage to the roof system will only get worse with time. Due to the freeze thaw cycle in the Northern climate damage increases rapidly. If left undetected this will lead to damage in other parts of the building structure and possibly the buildings contents.

During the day the roof system is heated by solar loading, after sunset the dry areas of the roof cools off while areas of trapped moisture retain heat. These areas are easily detected with our infrared camera.

Age of the roof does not matter; we have found leaks on newly completed systems.

By using infrared we can pinpoint the wet areas so that repairs can be made on the affected areas saving money by not having to replace the entire roof system.

Many commercial flat roof systems develop leaks within the first 2 years due to improper installation. Other factors are design problems or lack of maintenance. Once insulation becomes wet it can take decades to dry out. Wet insulation becomes a thermal conductor accelerating heat loss or gain on the conditioned air space it is meant to protect from the environment.

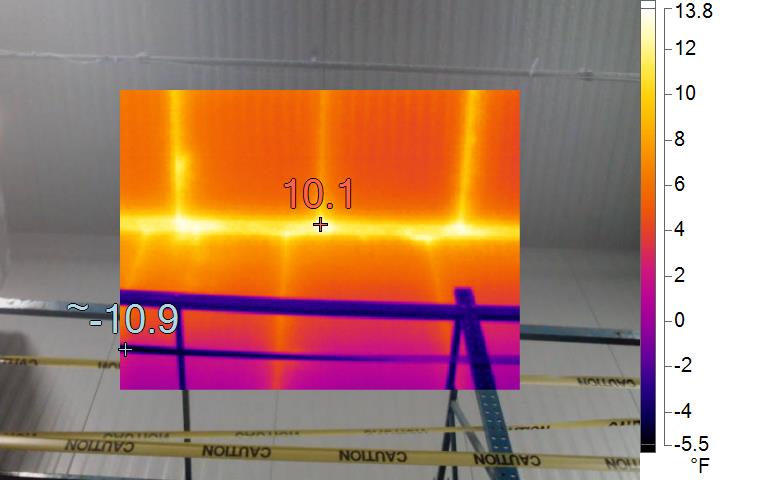

This Infrared image was taken from under the roof system looking up at the metal roof decking. The moisture infiltration can easily be seen in yellow color.

With certain types of insulation such as EPS or XPS a closed cell foam, moisture infiltration is difficult to see from the roof surface.

Buildings with no ceiling installed like big box stores can be thermally inspected from the interior.

With certain types of insulation such as EPS or XPS a closed cell foam, moisture infiltration is difficult to see from the roof surface.

Buildings with no ceiling installed like big box stores can be thermally inspected from the interior.

Collapsed Glass

Using Infrared this is a typical sign of seal failure in gas filled double pane windows creating negative pressure known as collapsed glass. Some windows have Argon or Krypton gas injected into the cavity between the glass panes.

The glass is separated by a spacer bar and sealed together. Argon or krypton gas has much better insulation qualities than just air.

Sometimes this can be detected with the naked eye by seeing condensation in the center of the window and sometimes can only be detected with infrared imaging as seen in the above photos. The large round window is only 2 years old.

The glass is separated by a spacer bar and sealed together. Argon or krypton gas has much better insulation qualities than just air.

Sometimes this can be detected with the naked eye by seeing condensation in the center of the window and sometimes can only be detected with infrared imaging as seen in the above photos. The large round window is only 2 years old.

Thermal Bridging at Purlins on Metal Buildings

|

Most metal buildings have purlins that are spanned between beams. On top of these purlins insulation is laid then the roof pans are mechanically fastened through the insulation to the purlins.

This design flaw is clearly seen in the infrared image in yellow. The insulation is pinched to nearly nothing causing thermal bridging. Notice the temperature of 112 degrees radiating into the conditioned air space with an 85 degree outside temperature. White Elastomeric coatings applied on the roof surface have a solar reflectance of 0.85 meaning the roof is now reflecting nearly all the heat back into the atmosphere. Clearly the roof in the photo is not coated with Elastomeric. |

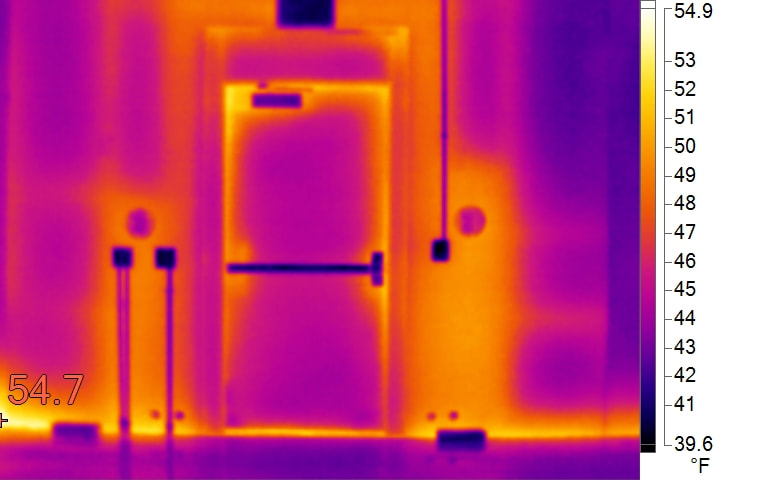

Thermal Inspection of Commercial walk-in Cooler's and Freezer's

Insulated panels for refrigeration and freezer units are engineered typically with a tongue and groove design with gaskets on the outer edges, they are tightly locked together with cam locks.

Sometimes the joints between the panels may not be locked down properly creating thermal bridging as seen in the photos above. Often times even newly built refrigeration units have faulty construction causing heat bridging.

Heat bridges result in an overall reduction in thermal resistance. This all means that heat is transferring into the refrigerated space costing you money.

Sometimes the joints between the panels may not be locked down properly creating thermal bridging as seen in the photos above. Often times even newly built refrigeration units have faulty construction causing heat bridging.

Heat bridges result in an overall reduction in thermal resistance. This all means that heat is transferring into the refrigerated space costing you money.

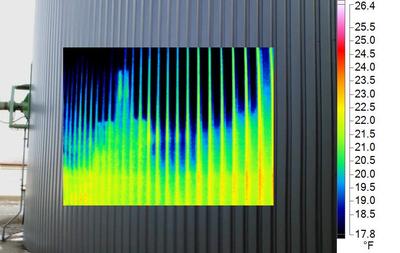

Thermal Inspection of Anaerobic Digestion Tanks

The thermal inspection of these tanks posed a problem. These tanks were constructed of 14" thick concrete walls covered with rock wool and polystyrene insulation with a steel cladding. The liquid manure inside the tank is heated to a temperature of 104°F.

We were onsite to determine what level of solids (sand) has settled to the bottom of the tanks using Infrared Thermography. The photo's above show a wave anomaly that varied between 2 and 10 feet high.

We were onsite to determine what level of solids (sand) has settled to the bottom of the tanks using Infrared Thermography. The photo's above show a wave anomaly that varied between 2 and 10 feet high.

Infrared detection of grout filled cells in CMU (Concrete Masonry Units)

Infrared inspections assist in assuring that your building is within design specifications with regard to material, structural integrity and thermal performance.

Grout filled cells shown in red are cooler temperatures, yellow warmer areas are the unfilled cells. It is very important during construction that all cells are filled and depending on the design that they have reinforcing steel installed.

Using Infrared Thermography as a detection tool for filled cells is the easiest and fastest method verses the older method of busting out sections of the concrete blocks to check for filled grout cells and reinforcing steel.

Grout filled cells shown in red are cooler temperatures, yellow warmer areas are the unfilled cells. It is very important during construction that all cells are filled and depending on the design that they have reinforcing steel installed.

Using Infrared Thermography as a detection tool for filled cells is the easiest and fastest method verses the older method of busting out sections of the concrete blocks to check for filled grout cells and reinforcing steel.

Infrared thermography can find core fills in CMU but it cannot locate reinforcement re-bar in block walls or slabs.

We use a US Radar concrete scanner to pin point rebar and conduit in walls and slabs

GPR Wisconsin is another division of The Gardner Company

We use a US Radar concrete scanner to pin point rebar and conduit in walls and slabs

GPR Wisconsin is another division of The Gardner Company

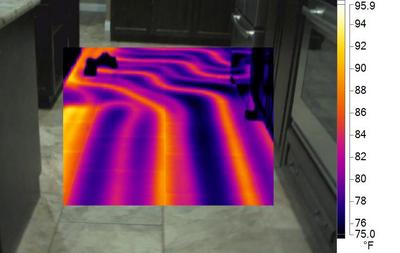

Infrared Imaging to Detect Radiant Heat Leaks

Radiant heat systems are installed in floors of many homes and businesses and are not visible with the human eye. These systems use continuous hot water supply lines.

A yearly inspection is essential for the detection of leaks or potential failure in the system. A leak can cause major property damage if not detected and repaired promptly.

These leaks can easily be detected and pin pointed using Infrared Thermography saving both time and money.

A yearly inspection is essential for the detection of leaks or potential failure in the system. A leak can cause major property damage if not detected and repaired promptly.

These leaks can easily be detected and pin pointed using Infrared Thermography saving both time and money.

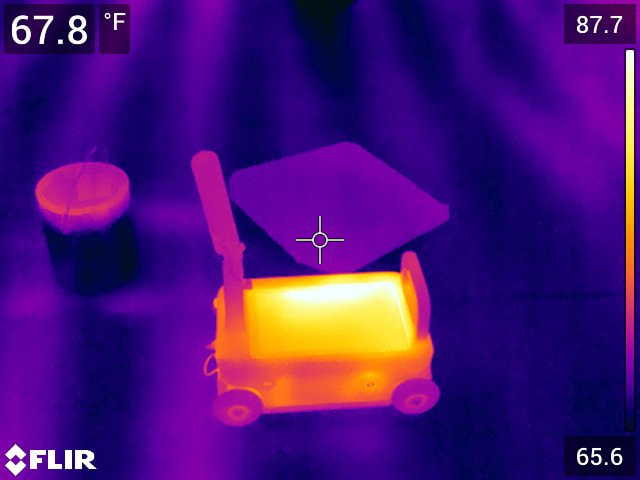

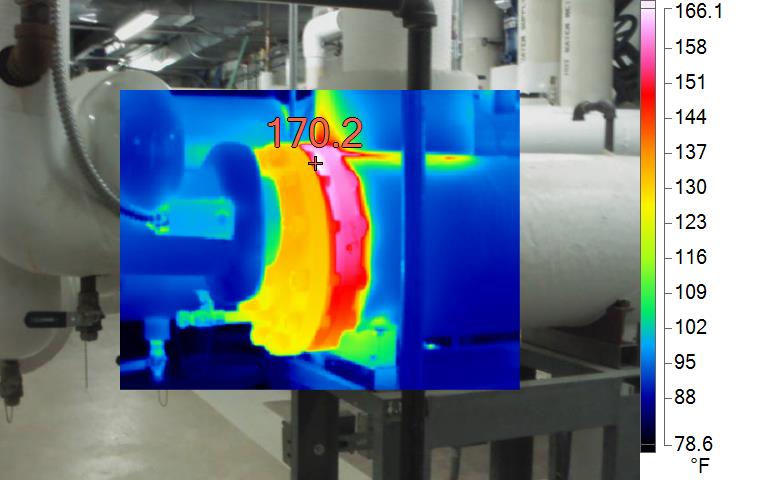

Thermal Imaging of Mechanical Systems

Infrared imaging is the go to method for monitoring mechanical equipment. Infrared allows for monitoring temperatures and thermal patterns accurately while the equipment is online and under full load. Overheated bearings, rollers, shaft misalignment, pulleys or lubrication failure can all be detected before a costly breakdown occurs.

"Thank you"

To the Outstanding Companies that trust Infrared Wisconsin as their Thermographer along with Hundreds of Homeowners and Building owners.

To the Outstanding Companies that trust Infrared Wisconsin as their Thermographer along with Hundreds of Homeowners and Building owners.